Founded in 1941, KI has been building and designing much more than furniture. They’ve created a furniture-design approach focused on empathy and understanding. It’s this philosophy that has led it to become one of today’s leading furniture solution companies, providing customized design services and bringing their client’s most unique visions to life.

Here the team from KeyShot sits down with KI Digital Marketing Manager Angela Koltz, as well as Senior CAD Training Specialist Jennifer Burke and Senior Industrial Designer Rob Wurm.

Website

Modeling software used: Creo

Tell us a bit about the background of KI and how the company has grown.

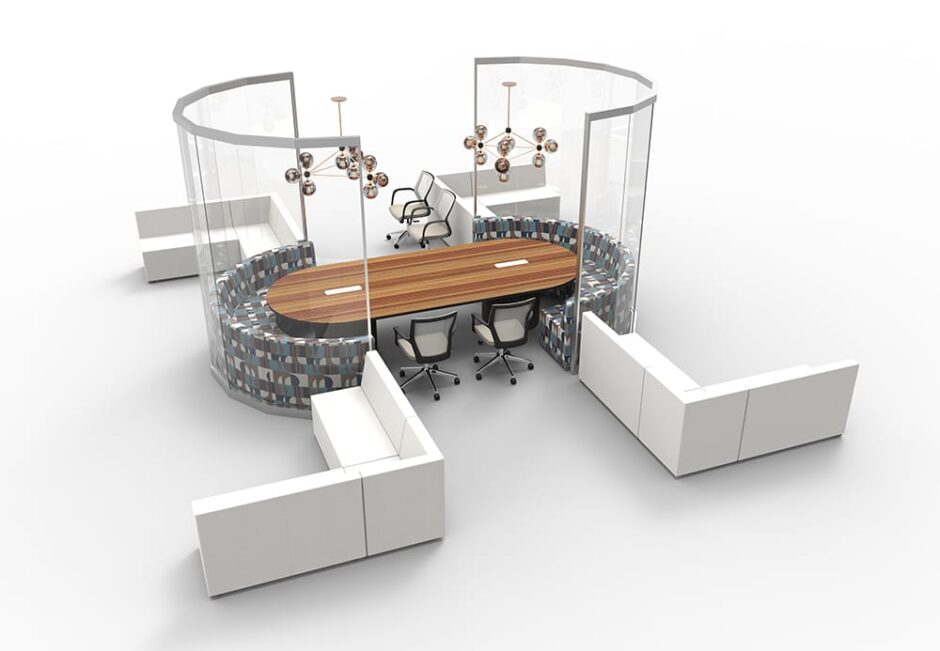

Angela Koltz: Since it began, KI has created compelling environments that bring interior design visions to life, approaching each project with a philosophy of simplicity, universality, and connectivity. The whole idea is to create unique and inspiring spaces for its clients, without sacrificing the functional aspects of the products they make. KI has kept the same ideals since its inception over the years and is committed to maintaining its human-centered design philosophy.

What are some of the challenges KI has faced over the years?

AK: In terms of producing high-quality rendered product images, it can cost upwards of $100,000 for images for catalogues, the KI website, and other marketing materials. Thankfully, KeyShot has helped us drastically minimize those costs, as well as made it easy for our designers to produce renderings of new products in just a few hours.

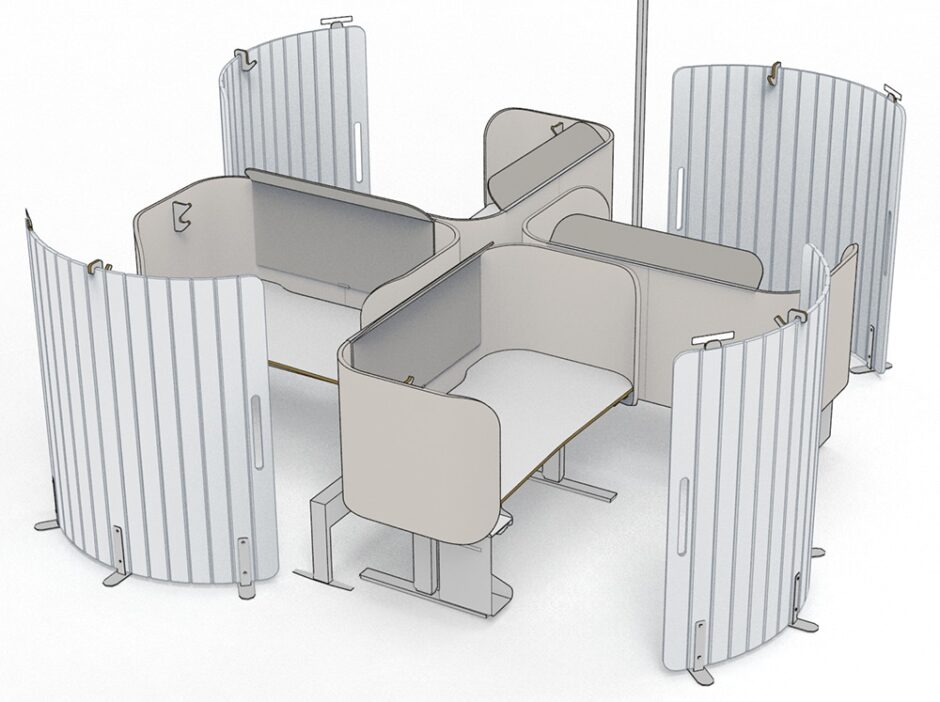

Jennifer Burke: Our design team employs AutoCAD to create furniture layouts, then employs KeyShot to put on the final touches, applying finishes to make the image come to life. This only takes around 30 minutes, something that AutoCAD could never do.

What are some of your favorite KeyShot tools and services?

Rob Wurm: KeyShot’s intuitive interface and tunable render quality produces pixel-perfect images and animations. That’s why I’ve stuck by it for so many years. Some of my favorite tools the software contains are its depth of field, light shaders, UV and Bump mapped textures, and quality backplate renders for larger render environments. I’m also excited about the KeyVR integration solutions it’s rolling out.

JB: The software makes it easy to organize all the tools you need into a library for various projects to improve efficiency; for example, our Paints and Plastic materials. This eliminates the need to re-create a material for each rendering and improves accuracy, that way the material is exactly the same on each rendering.

I also love the ability to use the DPI to scale our textiles. Typing in the DPI automatically sets the pattern’s repeat accurately. Also, the ability to create 360-degree renderings and send a link to anyone, who can then rotate around the rendering, is jaw-dropping.

How has KeyShot changed the way you work?

JB: It became a new world seeing finishes. We definitely did multiple revisions for finishes which was different for designers to grasp at first. Instead of spending time changing the 2D layout around we were spending time just changing finishes on renderings. 12 years ago, that was an odd concept, but now it’s normal and part of the workflow.

RW: KeyShot brings my ideas to life by taking my sketches into a 3D modeling program and then rendering them in the context of the environment they’re designed for. KeyShot has been so powerful in visualizing furniture and creating winning projects. For example, a healthcare bench I designed for hospital exam rooms that could be shown in the hospital room that’s still being built; the architect choose KI because they could see how it fits in their future building space.