Norway is a long stretched, mountain filled country with a strong heritage of spending weekends and holidays skiing and relaxing at the cabin. While most cabins are passed down through generations and mostly used by the family and close friends, we now see a younger, modern generation entering the market. Heim Hytter aims to fulfill the needs of this generation. A generation that has grown up with modern technologies and seeks products and services to help improve and simplify their lives. Here, we learn how they use KeyShot to communicate this.

What sparked the idea for Heim Hytter?

Heim Hytter (Norwegian for Home Cabins) was established in 2019 by three childhood friends: Richard, Marius and, myself, Leo. After finishing my master’s degree in industrial design in 2017, I started my own company, LeoBoe Design, a small design consultancy working on everything from packaging and sporting equipment to elderly walkers. I shared office space with Richard, who at the time was managing restaurants. We wanted to aim bigger and started spending our “downtime” brainstorming business ideas to live out our shared interests: architecture, design, and new trends in the sharing economy. We noticed a hole in the market and a new production possibility. Cross-laminated timber (CLT) production was set to start in Norway. This prompted the idea to design a CLT cabin construction system, and with it, a cabin designed to meet the needs of our generation.

What’s unique about the design process at Heim Hytter?

The design process at Heim Hytter is unlike all our competitors. First of all, we are not architects. Designing for CLT production requires skills in industrial design to make production affordable. CLT is produced in a factory. Starting out as raw timber at the start of the production line, planed and cross glued into elements up to 16 x 3,4 meter and formatted by precision CNC machinery. CLT production is unlike traditional building construction. We have spent over a year working in collaboration with Splitkon (the factory) designing a CLT construction system suiting their production facilities here in Norway. The result is a construction system able to configure into a wide range of cabin proportions and shapes with mostly the same base parts and without the need for reengineering the building’s load-bearing structure. This has enabled us to cut pre-production and production cost by almost 50%, offering a high-quality product at a reasonable price.

What is the primary 3D modeling software at Heim Hytter?

Coming from industrial product design, I use SOLIDWORKS for 3D design. SOLIDWORKS allows us to communicate with the factory and export file formats readable by their machinery, as well as create detailed construction drawings of all custom designed products, such as the kitchen. While SOLIDWORKS might not be the fastest CAD software for architecture, the assembly and configuration capabilities, and ability to communicate with the factory is a huge money and time saver.

Where in the product dev process is KeyShot used?

KeyShot has been a major part of our development process. From early concepts to the finished product, KeyShot has been used to visualize our ideas. We render images and animations after every major design iteration throughout the process as well as using live VR to evaluate sizes from a human perspective.

What are some projects KeyShot has been used on?

While our initial plan was not to use renderings in the launch of our brand, other plans had to be made when COVID-19 hit. Construction of two demo cabins was set to begin in April 2020, to be photographed and sold. This quickly became a high-risk project and a different launch strategy had to be made.

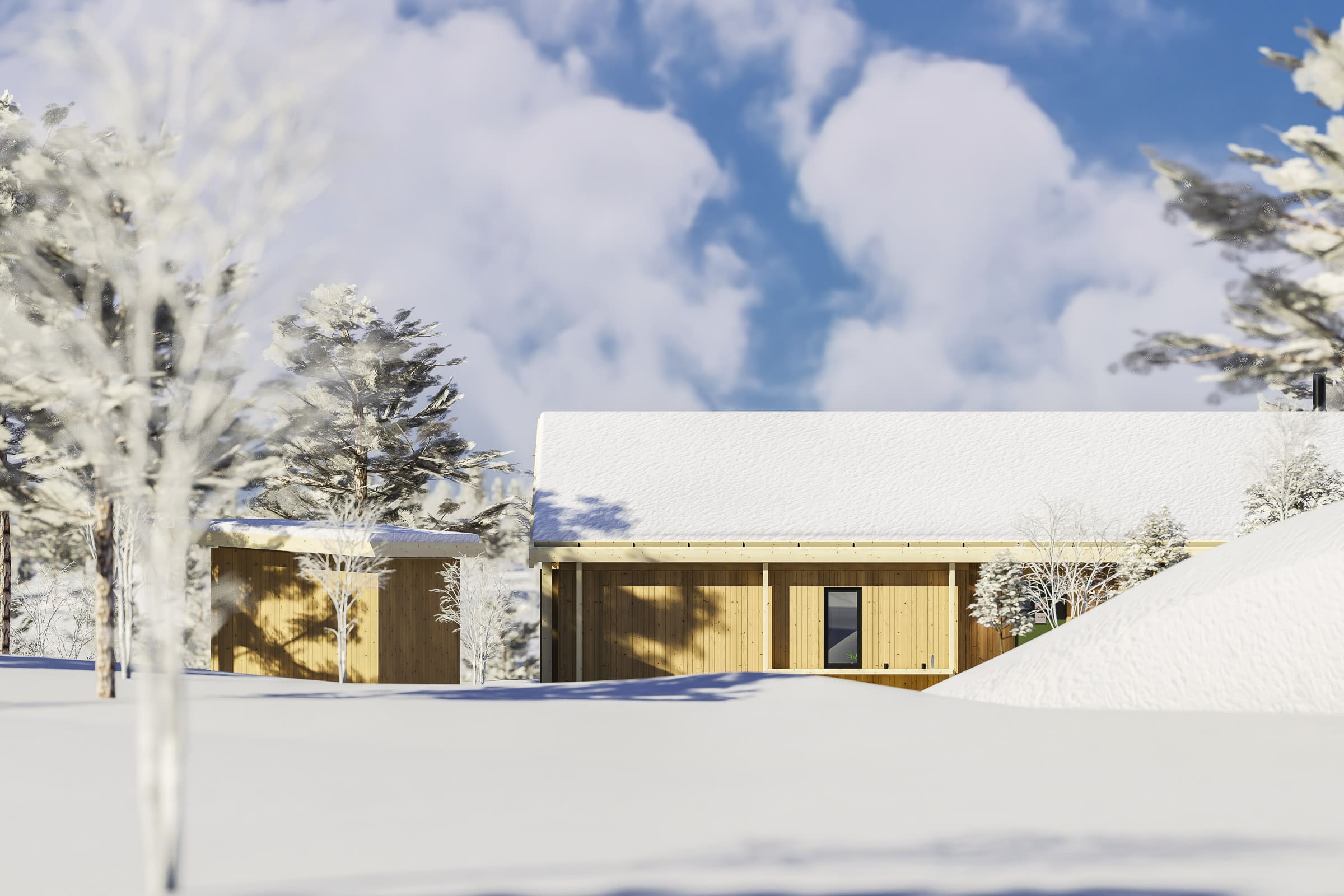

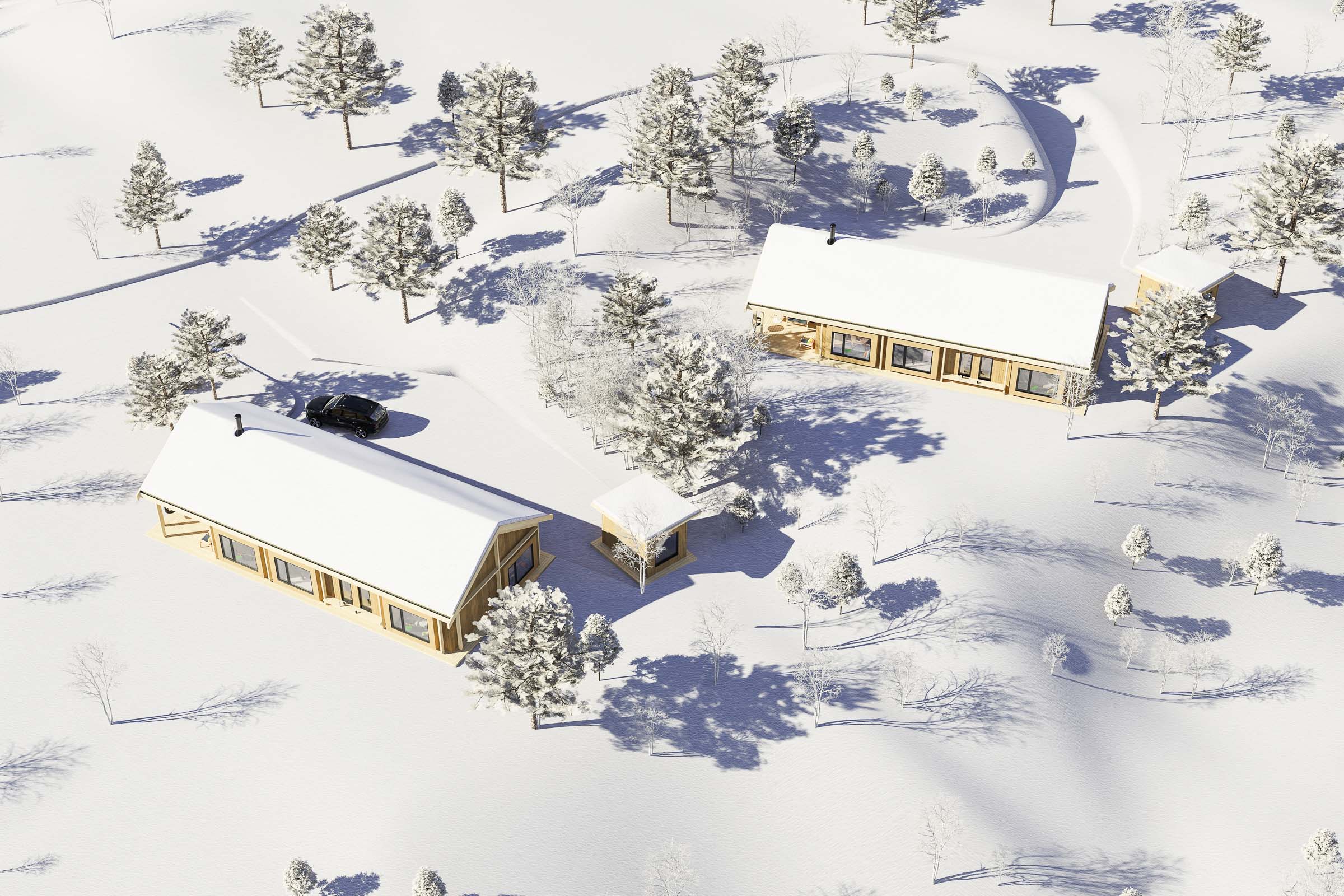

KeyShot became our savior. KeyShot had, so far, been used to create “simple” studio renders and some photoshopped posters, mainly to be viewed and evaluated by us. We needed photorealistic renders to convince potential buyers of our product. We tried using 3D scanned environments of the building site without much luck. The solution became recreating three acres of the site and surrounding land to truly create a reality of being there.

After two months in SOLIDWORKS and KeyShot, I created a virtual world ready to visualize for our clients the true quality of the Heim cabin. The scene is by far the biggest we have created with over 3.8 billion triangles, 250 cameras, 40 VR cameras, 130 lights, 50 environments, and animations to open/close all doors and drawers. The result has allowed us to digitally recreate the experience of being in a Heim cabin at Veggli, where the first two cabins will be built this fall/winter. All images used in today’s website and social media are created in KeyShot. Viewers can also experience Heimhytta at Veggli through our virtual cabin trip.

This KeyShot + Thinglink feature is a fun, interactive way for our customers to become familiar with the cabin and surrounding site. It can be viewed as 3D panoramas on desktop and mobile or as a full VR experience. This is a feature we will continue to use and improve upon in the future.

Overall, how has KeyShot helped save time, money and/or improve quality?

Coming from product design, I had already been using KeyShot to visualize products for years. I was familiar with the software and deeply impressed by the realism and esthetics of KeyShot. I wanted to try using it for detailed architecture. It has taken quite some time, but when finished we are now very satisfied with the result. Many of our competitors use renders in their development, sales, and marketing, but no one used KeyShot. The aesthetic characteristic of a KeyShot render has helped us stand out in the crowd and build a unique identity.

High-quality visuals have also helped us attract better-collaborating partners and secure improved deals with suppliers. What lies ahead? Heim Hytter is now entering an exciting time. While COVID-19 is an enormous crisis, closed borders and home offices have made cabins more attractive than ever. We launched the brand on July 20th, and our first project is set to hit the market on September 1st, with construction set to begin in the weeks after. This will be a huge milestone for us and the first time we will experience the cabin in full size. In the years to come, we will continue to explore the possibilities of our construction system and creating new models while also expanding into services to make owning and renting a Heim cabin even easier.

What advice would you give to others interested in doing what you do?

It’s a hard question to answer. Everyone is different and every business has its own criteria to be successful. But I believe that to make it in any business, you must love what you do. A good idea or good design takes time. Usually, twice as much time as you first think. It is a craft that requires patience. The devil truly is in the details and details require passion.

See more at heimhytter.no/