WARDJet is an Ohio-based designer and manufacturer of waterjet cutting systems that provides highly productive, reliable, and intuitive waterjet solutions made in America. For over 22 years, WARDJet has provided their knowledge and Tailored Waterjet Solutions to the manufacturing industry. Wayne Silasi, Marketing Communication Manager at WARDJet, tells us more about their design process and how KeyShot help them communicate their product.

wardjet.com/

What’s unique about the design process at WARDJet?

WARDJet is a vertically integrated manufacturer with nearly every major component manufactured right here in our Tallmadge, Ohio facility. With 100% of all design, engineering, and assembly done in America, WARDJet is able to innovate the latest technologies at a rapid pace. Our production facility is located right alongside our headquarters. This close proximity and open line of communication accelerate our product development and time to market.

How does KeyShot help you in the SOLIDWORKS/Maya workflow?

How does KeyShot help you in the SOLIDWORKS/Maya workflow?

KeyShot has been instrumental in allowing us to provide up-to-date product visuals that would otherwise be impossible. Used in many areas of our product development pipeline, KeyShot’s LiveLinking technology allows us to fluidly work between applications like SOLIDWORKS and Autodesk Maya.

KeyShot is, hands-down, the most versatile tool in our marketing toolbox. Initially used to provide realistic product visuals, we soon found that KeyShot is capable of much more. We use KeyShot for product development, tradeshow visualization, motion studies, interactive web animations, product turntables and even product configurators.

What are some projects KeyShot has been used on?

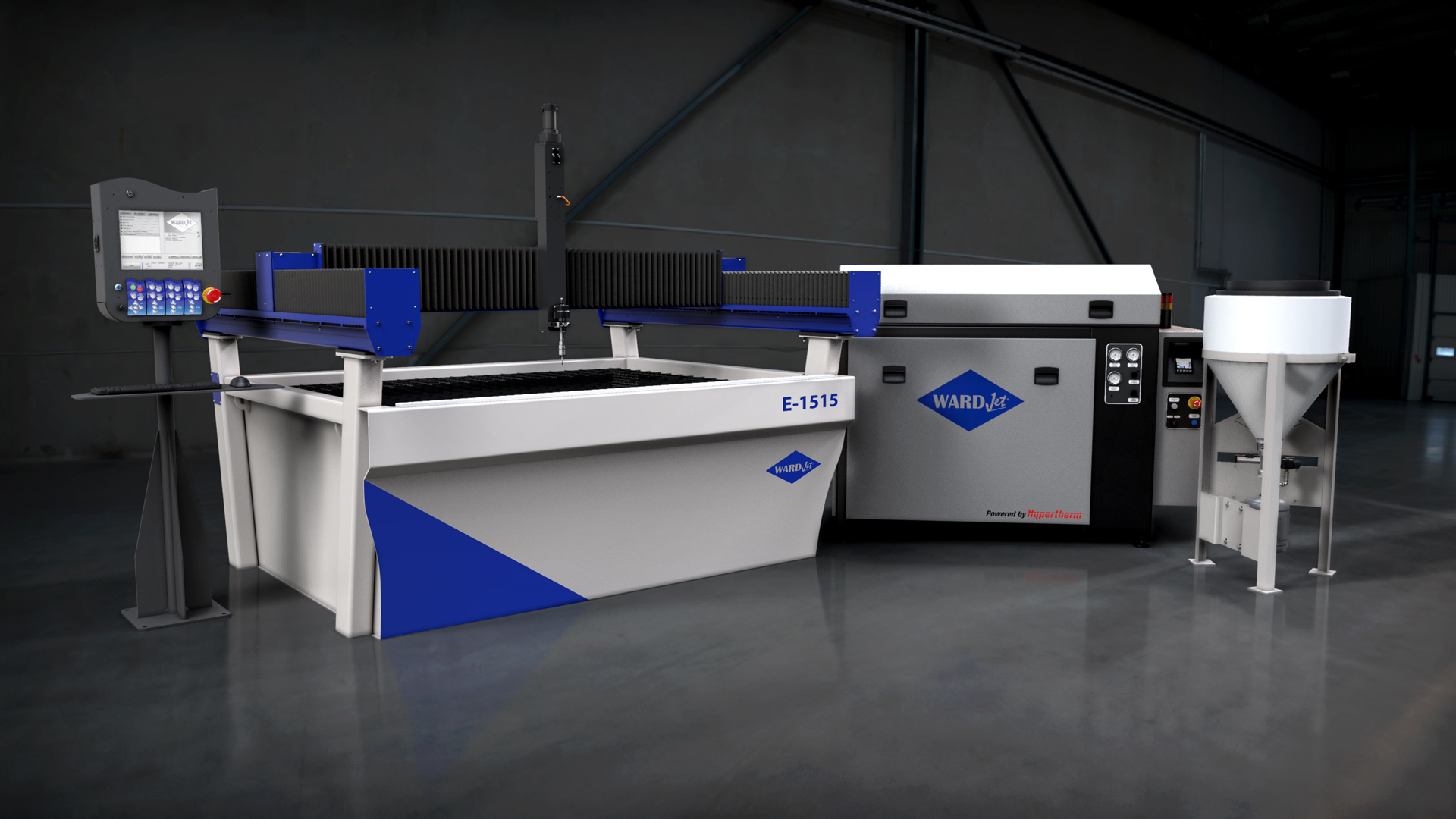

With our unique system of interchangeable parts and accessories, our customers are always able to equip their waterjet with the latest innovations at a fraction of the cost. Infinitely expandable and modular, there are over 100 million possible configurations. That being said, it is highly unlikely to see the same configuration twice – let alone take a photo of that configuration.

KeyShot has enabled us to, within minutes, create a realistic visual for any particular product configuration. KeyShot has also allowed us to clearly explain our modular system through exploded product views and extended animation – something that would be impossible using traditional methods.

Overall, how has KeyShot helped save time, money and/or improve quality?

After years of using biased render engines with endless parameter tweaking and lackluster results, KeyShot’s real-time, scientifically accurate rendering engine was truly liberating. It allowed us to spend more time doing what we do best instead of tirelessly tweaking sliders.

At its core, KeyShot is a visual communication tool. If we need to explore an idea or concept, there is no better way to communicate an idea than putting it down on paper or, in this case, putting it into KeyShot. A picture is indeed worth a thousand words – with KeyShot, maybe even millions.

What advice do you have for others interested in doing what you do?

My advice, regardless of what you want to do, is to be a life-long learner. To constantly reinvent yourself year after year, month after month and even week after week. Having a catalog of real-world experience allows you to be able to think critically – one of the most career-advancing skills you can have. It’s tempting early in your career to completely master a tiny set of skills – be it software, facts, procedures – but, I would advise that it is more important to know how to find the answer than simply reciting the answer.