Website: makerbot.com

Challenges:

- Convey complex interactions between moving components.

- Improve collaboration and communication between internal teams.

- Showcase the redesigned internals and features of their new product.

Solution:

- Use KeyShot Animation to communicate functionality and design intent.

- Create basic scenes to share and discuss among teams.

- Composite KeyShot render passes and animation sequences.

Results

- Stakeholders and staff excited about the product.

- Better decisions made up front, in less time.

- Engaging visuals for latest product launch and marketing.

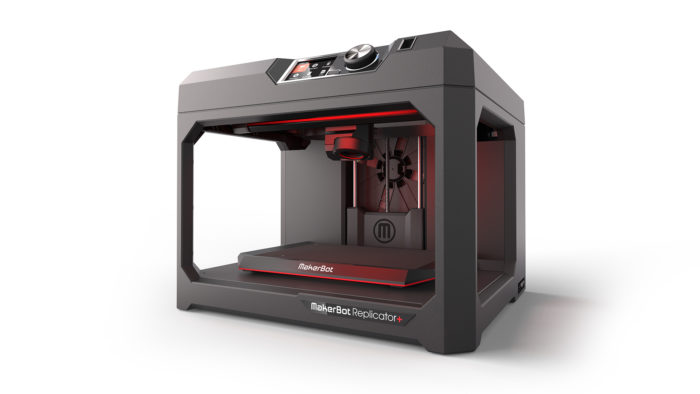

At first, MakerBot used KeyShot to analyze their designs in true-to-life lighting scenarios and develop visuals for design presentations. After working with the software consistently for a few months, MakerBot realized how they could leverage the power of KeyShot for the majority of its Marketing Assets. “Over the years, we have created hundreds of photo-real stills used to communicate our product’s features and aesthetics.” says Mark Palmer, Head of Experience Design at MakerBot. “In recent months, we began experimenting more with the animation tools for marketing purposes.”

“There were animations featured in our launch presentation at a recent MakerBot press event where we used them in combination with After Effects to showcase enhanced features of the new MakerBot Replicator+. We’ve also used KeyShot animation in our promotional video assets, such as the MakerBot for Professionals video.”

From Concept to Production

At a high level, MakerBot found the most powerful capability KeyShot offers their team is the ability to swiftly analyze product design and quickly make decisions. This has ranged from quickly rendering out design concepts to quickly exploring color and material options or analyze surface continuity for various parts. “We rely on KeyShot to help us align on and sell our design intent internally,” say Mark. “It has become a powerful tool to excite stakeholders and staff about the future we are designing. KeyShot has helped us make the right decisions for our products from the first day of concepts to the day parts are sent out for tooling.”

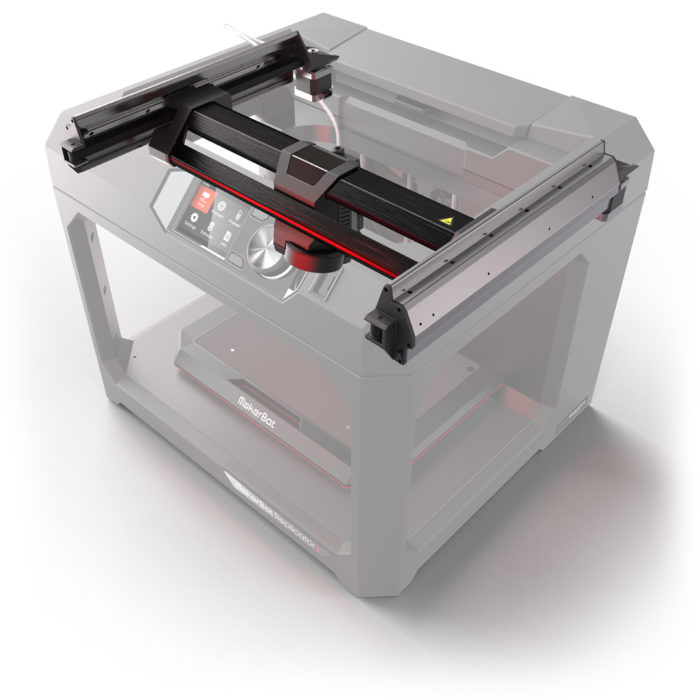

When considering how to illustrate the functionality of the product before it’s even made, motion is a major factor needed to explore and convey the interactions between moving components, but conveying motion through static images was a challenge.

“When we were working on initial concepts for the redesigned X-gantry in the new MakerBot Replicator+, we envisioned an almost magic gliding motion between the extruded aluminum cross-member and the carriage (the part that holds the printer’s extruder) that moves along it. As we explored and rendered design concepts, we initially created a basic looping animation that conveyed to the team how these parts would relate and slide relative to each other. That simple KeyShot animation was a great example of quickly creating compelling assets to explore, communicate and sell an idea. People got excited and the concept made it into the final product.”

“We’ve also started to put a lot of effort into our packaging design in the last few years and KeyShot played a big role in helping us articulate the value and vision for doing this. We’ve used KeyShot to create basic scenes of various package and box form factors without artwork, which we can then share with our marketing team designers, exploring visual design concepts and working in harmony with Illustrator and Photoshop graphic comps. This workflow is a quick and efficient way to explore design concepts and a big enabler for collaboration between the teams, and once again, everyone gets excited by the results.”

“We’ve also started to put a lot of effort into our packaging design in the last few years and KeyShot played a big role in helping us articulate the value and vision for doing this. We’ve used KeyShot to create basic scenes of various package and box form factors without artwork, which we can then share with our marketing team designers, exploring visual design concepts and working in harmony with Illustrator and Photoshop graphic comps. This workflow is a quick and efficient way to explore design concepts and a big enabler for collaboration between the teams, and once again, everyone gets excited by the results.”

Nailing a Critical Launch

Working toward the launch of the new MakerBot Replicator+ and MakerBot Replicator Mini+, the team knew they wanted to showcase the completely redesigned features and internals of the printers. “As we approached the design of the new printers, we decided that the exterior ID of these products wasn’t begging to be changed. They’ve won design awards and are very iconic, so in the development of the new printers we really worked intimately with our mechanical engineering team to optimize the performance, design, and ergonomics of many of the secondary components in and around the build area, such as the Z-stage and build plate, and the gantry system.”

“When it came to launching the products, we wanted to emphasize what had changed internally, but do so in context.” To do this, they created multiple render passes for the product exterior, product internals, and combined various animation sequences. Mark says they, “composited all of these together in After Effects, along with explanatory motion graphics. The result was a really engaging fly-through of the product, selectively exposing internal components along with supporting information. It was a completely different way of showing our products and it was one of the most exciting parts of our presentation to the press.”

Did it take weeks and months of preparation? Not quite. “We undertook this very close to launch and were able to get it done in only a couple days. The tools and reliability of KeyShot (along with a 32 core workstation) played a critical role in making it happen!”

On KeyShot Animation

“For our fly-through animation during the launch event, we used a combination of all the animation types (object translation and rotation, camera orbits and pans) to create unique animations that are specific to features we want to show off. We must say, a slow orbit or turntable always looks hot.”

On KeyShot Resources

“KeyShot’s learning resources have helped us immensely over the years to teach us new software features and how to create trickier materials. Each time we watch a webinar, we learn low level information like new techniques and higher level concepts around the way certain materials behave.”