The Iowa State University’s College of Design is a top-tier school, unique as one of only three colleges in the US with a comprehensive approach to teaching about design while providing students with the widest range of access to different design disciplines and their complement. Applying their interests and learning their craft, students focus on the goals, changing the world for the better, not simply adding more products to it, but developing products that last and change lives. They work through ideas with physical models, creating and using KeyShot through the process to help in bringing their ideas to life. We talked with Steven M. Herrnstadt, Professor at Iowa State, more about their program and how KeyShot has helped.

Iowa State University – Industrial Design Department

Modeling software used:

SolidWorks

design.iastate.edu

The Iowa State University Industrial Design Department (INDD) is unique indeed and a highly sought after college by students around the world. On average, they will receive 170 applications for 35 spots each fall. As Steven tells us more about the program, it becomes no surprise that the learning environment at ISU is in such high demand.

The Iowa State University Industrial Design Department (INDD) is unique indeed and a highly sought after college by students around the world. On average, they will receive 170 applications for 35 spots each fall. As Steven tells us more about the program, it becomes no surprise that the learning environment at ISU is in such high demand.

What’s unique about the Industrial Design program at ISU?

First and foremost, David Ringholz, Chair, Industrial Design of ISU and the collection of faculty he has assembled. We integrate all our classes. By that I mean during the classes in CADD, for example, we have the students not only do introductory tutorials but we have them bring in projects from their other studios and classes and work on them as part of the CADD courses. Our materials and process class is integrated across the CADD class and the other studios. Any student or faculty is invited to any critique. Our faculty is diverse in terms of experience, industry segment, background, and nation of origin. For example, we have people with backgrounds not only in industrial design, but in the fine arts, psychology, mechanical engineering, and electrical engineering. Some of our faculty have multiple backgrounds. We have very young faculty and shall we say “chronologically mature” faculty. Each faculty member has particular strengths and all have certain commonalities which make teaching and communication easier. The students see that and se the faculty cooperating on various parts of a project or even teaching.

Above all our program and our classes are fluid. One course flows into another concurrently and sequentially. We do not, for example draw a line between CADD/digital rendering and analogue/hand rendered images. The students and faculty freely move among all types of rendering. Hand rendering is not sequestered only to hand rendering classes. Neither is sacred and can be combined with one another using each media’s strengths. If one wants to draw on a synthetic image (computer render) then fine as long as it advances the intent. Our students are trained to be proficient in both digital and hand rendering (what some call “legacy media” although we feel that both are current). My own feeling is that both are needed and the seamless ability to move between them and combine them when desired is an advantage.

We are in the College of Design and yet also well allied with the College of Engineering. We have set up a system of fabrication labs called the Resource Hub. Any student in the College of Design and the College of Engineering can share fabrication labs in the two colleges if they have taken and passed safety and training classes. We have access to CNC mills, CNC plasma cutting, laser cutting of various materials including stainless steel, various types of 3D printers including an Objet multiple material printer. We have access to glass blowing and to lamp work. We are in close proximity to the National Ames Laboratories which specializes in rare earth materials and is where leadless solder was invented. We are nicely situated between the Twin Cities, Chicago, Kansas City and Omaha. Des Moines is a rapidly rising cultural center as well.

How has KeyShot been integrated into the program?

It is introduced as a matter of course in the beginning CADD class. Each student gets a copy along with a copy of SolidWorks to install on their laptop or workstation. From that point on their presentations, whether for a poster or a client, are heavily based on images created by KeyShot.

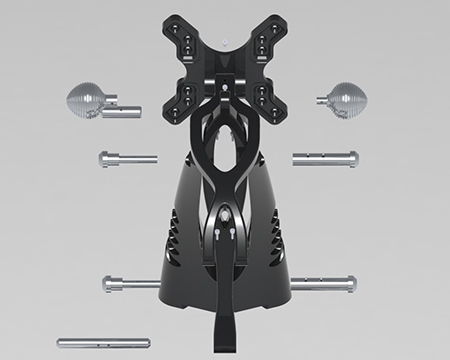

Their senior Projects/thesis culminates in a physical prototype and an expanded printed and bound process book. They are exposed to lighting and composition in KeyShot as if it were conventional photography. This includes the knowledge to match the lighting of their synthetic models from SolidWorks to an existing scene or photograph, the Kayak by Paige Mitchell is an example of that. They learn to create context images as well as exploded stills and exploded and articulated animations.

How has KeyShot helped ISU students/faculty save time, money or improve quality?

The best example of the quality jump was the first semester we brought in KeyShot. At the beginning of a studio sponsored by Calphalon in which the students made presentations to Calphalon designers, marketing people and engineers, the first illustrations on the posters and PDF projected presentations were hand rendered and digitally printed. They looked like very good student work. By the fifth week of the semester they had learned intro to SolidWorks and had just been introduced to KeyShot. The results were remarkable. Even the Calphalon people mentioned the jump in quality and verisimilitude.

The students responded to how quickly they could get polished results. I have spent years teaching animation, rendering, modeling and lighting using the main surface modelers. It took me a fraction of the time to get the students running decent renders on KeyShot. KeyShot presents a quick straightforward interface towards good looking and well lit images with studio and exterior lighting presets and a good selection of surfaces and materials for the student to play what if.

What are some examples of how KeyShot is being used or helping students/faculty?

In our sponsored studios the students present solutions and work in progress to real world clients. The real time renderer allows them to get a quick sense of what the final rendering will look like without committing to a final render until things are laid out the way they want–this applies to hero shots as well as context shots. Animated exploded images are straightforward and can be used as assembly images or as articulated models. I have also been using it to teach lighting and camera composition integrally with modeling.

[divider]