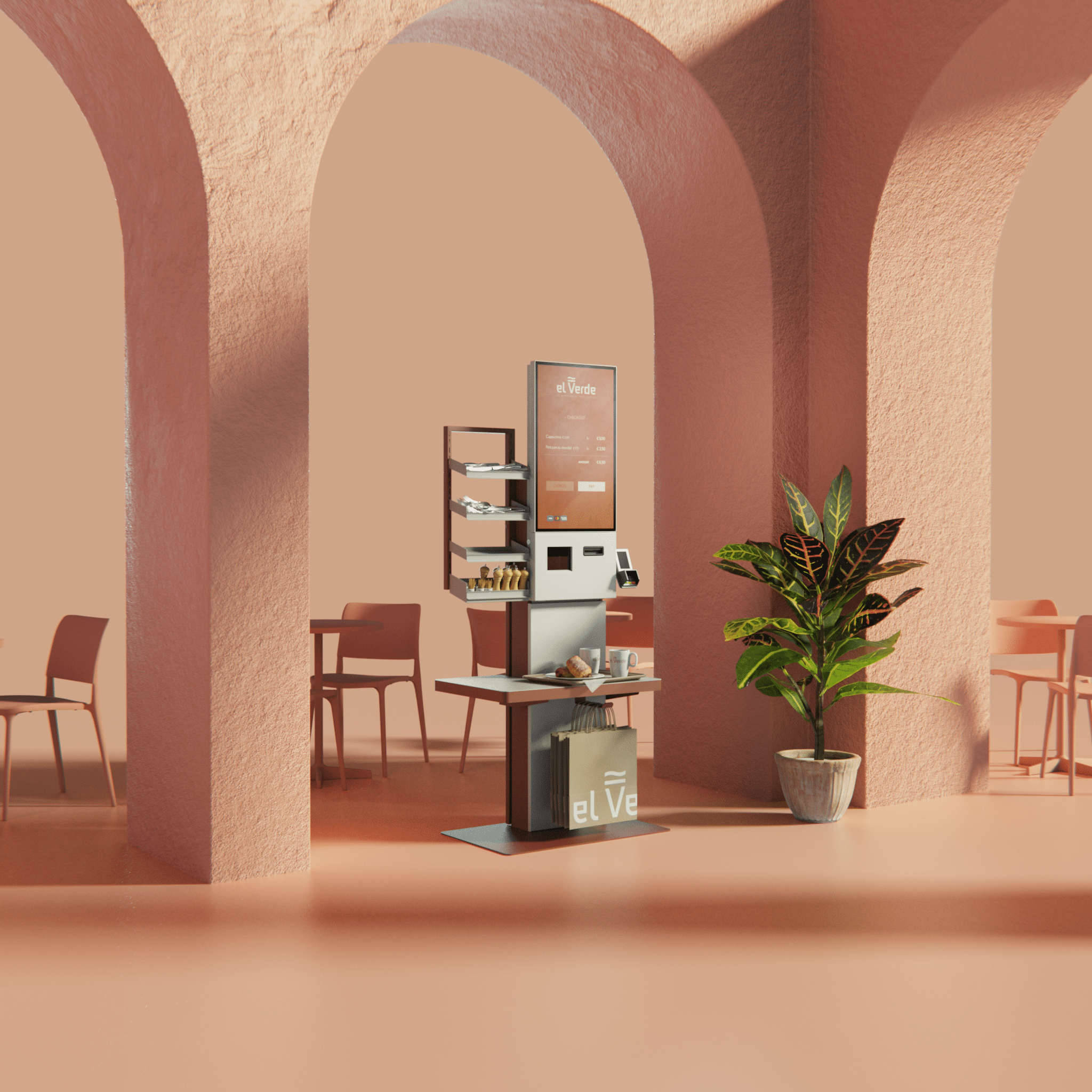

Over the last 50 years, Pan Oston has been the market leader in the Netherlands for full service cash register or checkout systems most often found at the grocery store checkout. Over the years, they’ve grown their product lines to self-checkout and self-service kiosks and expanding their sales to England, de Nordics, Belgium, France, and Germany. They use KeyShot to create the visuals that showcase their products with the highest level of realism. KeyShot partner, AESC B.V., recently spoke with Corné van Braak, Head of Innovation & Design, to learn more about how KeyShot has improved their process.

Website (NL) | Website (UK) | Facebook | Linkedin

Modeling software used: SOLIDWORKS

Located in Raalte, Netherlands, with origins as a metal manufacturing company, Pan Oston controls the entire manufacturing process from sheet metal and assembly to completed products. The majority of the specialists work from the head office in Raalte. In addition, there is a service team that is on the road and takes care of service and installations. From design to field services, Pan Oston has it all. Especially when it comes to design and engineering, Pan Oston distinguishes itself from the competition. The relatively large departments give the company and its customers a high degree of flexibility when it comes to custom-made solutions. This is where we find Corné and where KeyShot comes in.

What sparked your interest in Product Design and Engineering?

I went to school to become an industrial product designer and have now worked at Pan Oston for 17 years. I am a technician who loves thinking of new solutions to design. Trained in SolidWorks, creating products in 3D is a massively efficient way to develop products. My interest comes from the desire to create new things. In the end, we are shapers and creators. We want to show products like they are meant to be shown. With a sketch on paper, you can present the concept. With a CAD drawing, you can present the function and give context to the product. But when you really want to reveal the final design, with the designer’s intent, you model it in 3D and render it in KeyShot. I noticed people often already used KeyShot because they see the advantages, such as the speed of visualizing, which becomes faster as your speed improves. For us to be really photorealistic, KeyShot is the best tool. Over the past year, we started using the same workflow with the same materials and have started working better together ever since.

Where in the process is KeyShot used?

We work as an innovation and design department of seven people that are continuously innovating and renewing designs in the area of IT and product development. Once we have our product proposal ready, it is refined by our engineering department with SolidWorks. The basic model is further refined into something that can be produced. From that moment it has gone through the entire organization. Then prototypes are made for the concept to be presented.

We are specialists in customization, especially for retailers in Europe who like something special on their products. We have a number of basic configurations used to create a custom design for our customers. KeyShot allows us to customize the product for the customer and shift fast. The customer knows what they are getting much sooner and we can show, in detail, how the product will look. As a result, we save money on prototypes. KeyShot is also very nice for online marketing visuals as well as trade fairs we attend.

KeyShot allows us to customize the product for the customer and shift fast. The customer knows what they are getting much sooner and we can show, in detail, how the product will look.

What are some projects you have/the company has used KeyShot on?

Tipico, a provider of sports betting and casino games, is one of our customers. They expect added-value design and a distinctive product with a prominent form. KeyShot allows us to be more efficient in this area and capture it with the rendering of LED lighting for the products. We are also involved in a new self-checkout system for the market in Germany. For this, we have frequently used KeyShot to highlight the new features that differentiate it from products in other countries.

Overall, how has KeyShot helped save time, money and/or improve quality?

KeyShot has helped with the quality of communication, allowing us to show a more realistic version of the product. Previous software packages would create the wrong expectations. KeyShot contributes to a more realistic appearance that meets expectations. And since the team uses the same workflow with the same materials, we are able to work and make adjustments quickly.

What advice would you give to others interested in doing what you do?

Take advantage of KeyShot’s seamless integration with 3D software to generate product visuals quickly and easily. The ability to use KeyShot for GPU rendering allows you to generate renderings even faster, which not only improves the visualization process but also makes it easier to render animations. Materialization, composition, and lighting are childishly easy to use. At the same time, KeyShot has the advanced features to create unlimited possibilities.

“The ability to use KeyShot for GPU rendering allows you to generate renderings even faster, which not only improves the visualization process but also makes it easier to render animations.”