We were honored to jointly sponsor the Core77 Design Awards with Stratasys this year. With so many talented designers and teams, and many memorable designs, this was an incredibly challenging design award to single out one winner. What made the Core77 Design Awards unique is the detail that each team provided about how they used KeyShot in the process and what challenges KeyShot helped solve. In the end, we selected three for a variety of reasons but, in the end, had to make one selection to take home the KeyShot Prize.

Lucid Air for Lucid Motors

The Lucid Motors visuals for the Lucid Air mid-size car are beautiful. They capture the essence of what they want to communicate with the luxury EV for both the interior and the exterior. They used KeyShot to explore and range of materials, utilizing the toon material for quick development of outlines and KeyShot Animation to evaluate movable interior components. Altogether it was evident how they used KeyShot throughout the entire product development process. We’re proud to select them as the overall KeyShot Prize winner.

What challenges did KeyShot solve in the case of this particular project?

“During the design process, it was necessary to evaluate several movable interior components. The animation feature in KeyShot allowed interior designers to deliver many movable components to other colleagues. Rather than showing 2D images, the animation feature proved to be the best tool for presentation of the various components.”

“Another challenge that KeyShot helped to solve was the ability for the design team to keep pace with the engineering team. Designers were able to review the engineering data together with design data quickly in KeyShot in order to develop the best way to integrate the package challenges.”

Learn more at lucidmotors.com.

Monogram Creative Console for Monogram

Monogram’s modular, analog console for creative development stood out for its use of tone, shadow, simplicity, and axonometric projection. Whites can be challenging to capture and they did so beautifully. The in-situ shots really demonstrated the product’s versatility as well. Their use of KeyShot included using it for design decision making for geometry and materials, packaging shots, and a range of configurations for interactive web visuals.

What challenges did KeyShot solve in the case of this particular project?

“Using photorealistic renderings allowed us to use fewer physical prototypes during development, especially useful when shipping and in-person meetings were impacted during pandemic lockdowns.”

“Using KeyShot’s scenes and grouping features allowed us to create multiple iterations to find the best layouts and presentation for marketing materials. We achieved the desired creative direction quicker and with a lower budget, especially important for a startup like ours.”

Learn more at monogramcc.com.

CLMBR Connected for CLMBR

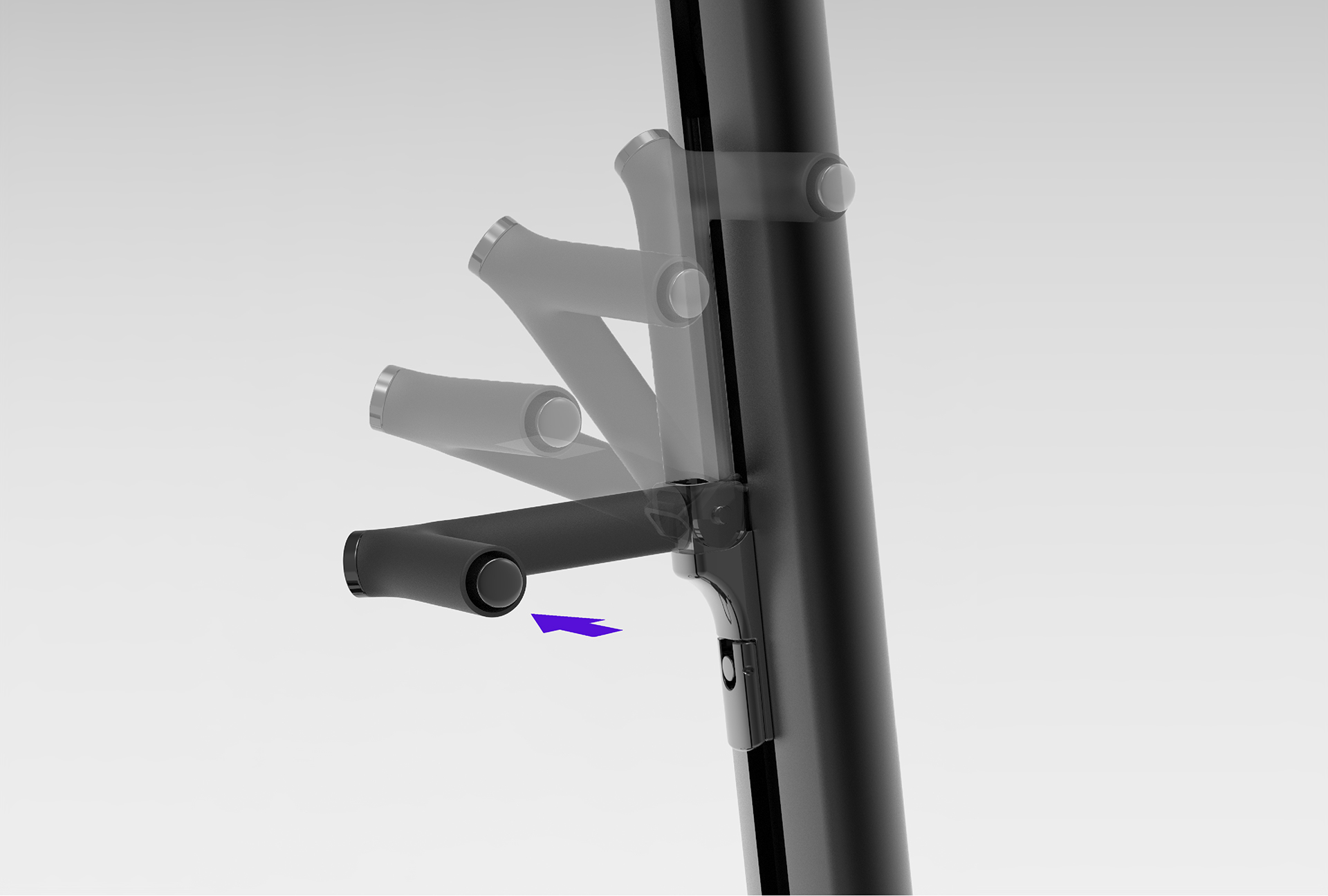

As the world’s first vertical climber, CLMBR Connect, captured our attention immediately in both its form and the technical visuals provided. They used KeyShot to help the teams across multiple geographic locations work in real time with each other to quickly iterate and improve the product. They took a challenge and used KeyShot to help turn it into a solution that benefited team, company, and customer.

What challenges did KeyShot solve in the case of this particular project?

KeyShot solved numerous challenges in our project. Specifically, KeyShot helped us evaluate quick changes during initial prototyping and pre-production all while working remotely due to Covid-19. Nothing beats reviewing physical samples but shipping those around to remote team members is time consuming and costly and KeyShot allowed our team to quickly review and modify parts, surface finishes etc. It has also allowed us to produce beautiful photorealistic renderings for use in presenting the product and company to new investors and the market.”

Learn more at clmbr.com.

KeyShot and Stratasys Collaboration

Stratasys and Luxion are extremely proud that the results of our collaboration are helping designers bring new products to market faster and more profitably. We are excited to share this news and workflow with the Core77 design community with our joint support of the Core77 Design Awards for 2021.

Almost any product designer will tell you that prototyping the shape of a new design with 3D printing is fairly easy. However, accurately simulating color, material and finish, or “CMF,” can take serious time and money. But, thanks to the latest KeyShot 10 3D rendering software and Stratasys J55™ and J8 Series 3D printers, it’s little more than just click and print.

The full-color, multi-material Stratasys 3D printers and the latest version of KeyShot from Luxion both now support the new 3MF file format. By saving designs to 3MF, KeyShot 10 produces files ready for printing, with accurate PANTONE™ Validated colors, bump mapping, and the ability to simulate textures like fabric, wood, and glass.

The new workflow enables the CMF design phase to start earlier in the design process and can also reduce 3D print modeling time of CMF models to a single day, while traditional modeling for final iterations can take from one to three weeks. Product designers can now reap the rewards of reaching design approval faster, shortening their product development cycles, getting new products to market faster-ahead of their competition and recognizing revenue sooner.